Pentacque srl - Industrial plants for water treatment

Industrial plants for water treatment - Via Maestri, 11 - Brescia

Tel. +39 030 3539154 - Fax. +39 030 3542719 - E-Mail: info@pentacquesrl.it

Realization treatment plants

Mechanical filtration, absorbents, and chelating deferizzatori

Mechanical filtration

The filtration process used to remove suspended solids in raw water or at the stage of settling of chemical plants.

The filtering is done using filters, which would allow a difference for those with serious, large flow stream.

I used to fill more beds are quartz filter, charcoal, activated carbon and zeolite granules, they are chosen based on the characteristics of the water to be treated.

For so-called mechanical filtration are used quartzite, anthracite, zeolite.

Pentacque provides filtration plants which are generally made of two or more columns with a speaker or speakers plate Candlestick and packing material, which varies by type and size depending on water to be treated.

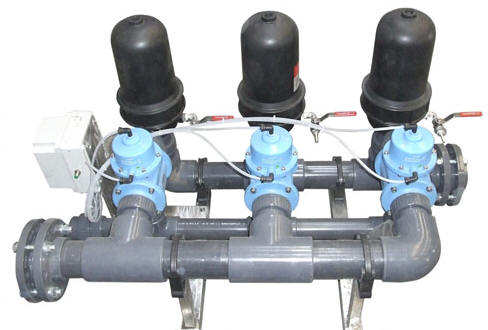

The piping of the filtration plants is usually made of plastic PVC valves consists of managing all stages "and work controlavaggio" all the management operations of 'filtration plant can be provided automatically by command of ball valves in PVC with pneumatic actuators, operated by Plc or even in manual version.

Our filtration plants have taken varying from 200 lt / ha 35mc / h.

Filtration absorbent

A solid body in contact with a solution tends to accumulate a layer of solute molecules on the surface because of the weak chemical bonds between the molecule and the surface of porous solid particles, the phenomenon is known as filtration to adsorption.

Our filtration using granular activated carbon, technical series are able to take this action by showing a remarkable affinity for organic compounds due to the extremely large surface area obtained by the activation process of steam.

The adsorption capacity of the plant filtration using granular activated carbon series technique is used to remove traces of pollutants from the water.

These chemicals include oils, surfactants, phenols, chlorides, pigments, organic solvents and organic matter in general.

Pentacque thanks to its experience in water treatment and after studies on the processes of absorption, it offers its customers a series of filters with various skills, assessing carefully at design speed, operating pressure, the contact time and type activated charcoal to be used, which makes it possible to achieve filtration plants and to maximize the absorption of chemicals unwelcome.

Chelating filtration with removal of heavy metals

The ion exchange occurs in reversible reactions between functional groups linked to a polymer matrix inerte "resin" and ions in the solution in contact with the solid.

The use of a polishing filter or chelating resins, is expected when the water quality caused by sewage treatment plants contain chemical physicists small percentage of metals undermining the security of compliance with existing tabular discharges in the process of purification.

This particular condition is solved with the use of chelating resins with selectivity scale of well-defined and evaluated according to the type of work recognized.

Pentacque suggests these filtration plants using resins with specific ability to remove the residual traces of ions downstream of the plant with fully automatic versions.

Filters deferizzatori

The iron can be dissolved in water or as a precipitate in suspension.

The iron-water does not involve any major problems, can be done by an ordinary mechanical filtration (mechanical filters, sand filters).

The removal of iron dissolved in the form, usually in the form of ferrous ion, should have its first oxidation to ferric ion, and its precipitation and finally after getting the form in suspension is carried to its mechanical filtration.

From a chemical dissolved iron in the form of Fe + +, must be transformed by oxidation in Fe + + +.

The chemical process iron through oxidation, may be thanks to the determination of oxidants before filtration through strong air insufflation, or through the use of filter materials such as zeolite manganese.

This process is achieved with the passage of 'water deferrizzare read through a special filter, capable of both the processes of oxidation and filtration.

The oxidizing capacity of the filter bed is maintained through periodic controlavaggio automatic filter.

The filters that Pentacque iron designs are made with a system of automatic and free of ordinary maintenance.